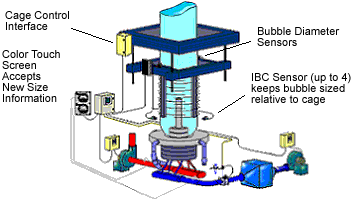

Automated Control Features for the DRJ IBC System

Automatic Blower Balance

What it does… The automatic blower balance (ABB) module for the DRJ IBC provides the function of balancing or nulling the supply and exhaust blower flow rates automatically. This feature speeds startups and eliminates the need to train operators to balance blowers. Only one setting change is necessary to increase or decrease air exchange rate.

Establishes Initial Balance.

During startup, finding the right balance conditions can take considerable time for a less experienced operator. The patented ABB system monitors the balance and adjusts the supply blower until it achieves the balance condition. In this case, the supply blower is flow matched with the exhaust blower, then the final balance is achieved.

Recovers from a Balance Disruption.

In this case, where the bubble is too big, slowing the inlet blower to help reduce bubble size is done automatically. This condition can occur during startup and during size reductions. After the bubble reaches final size, the blowers are rebalanced.

Layflat Control

What it Does… The Layflat Controller uses a second size feedback loop (see below) from the bubble to set and maintain a specific bubble size. The system comes with a 6 inch color touch screen which provides a variety of other features such as trending, troubleshooting, and commissioning tutors. The system comes with a compensation function that allows for the drawdown in the film as a result of tension between the primary nips and the winding nips.

How it works… By using a second set of sensors just above the sizing cage, the system remeasures the bubble to get the final diameter. From this diameter, the layflat is calculated and includes an adjustable factor for shrinkage or drawdown. This configuration is less dependent on line speed because of the short distance between the sensing point and the die. Also, there is no variation in the distance between the IBC and layflat sensors, which keeps the controller working consistently for all line speeds and when oscillating nips are used.

Benefits…

Very good for managing on-fly-size changes, works well with gusseted film, reduces the time it takes to get the bubble on size and minimizes changes in layflat from day-to-night changes in the frost line height.

Automatic Cage Control

What it does… The auto cage control system allows a single operator step for changing size… enter the desired layflat and the system does the rest. Even manual cage position changes are easy and do not require putting the system into the manual mode.

The automatic cage position changes take place during startup, on-the-fly size changes, and during day-to-night changes in the frost line height. Compensation for cage speed and backlash are provided.

How it Works…

The auto cage controller uses information from the layflat controller and IBC system to automatically manage the bubble from one size to another. Feedback to the automatic blower balance module and from the IBC module ensures bubble stability is maintained during the size change.

When the operator enters the new layflat size, the system automatically processes the size change as a series of steps to further reduce the chance of losing the bubble. Typical size change times are two inches per minute (50mm/min). Air ring adjustments still have to be managed by the operator.

Compatibility…

The IS-IBC1 Auto Cage Controller does not use any position encoders so virtually any sizing cage with a motorized size adjustment will work with the IS-IBC1 system. Cages that move too quickly for fine positioning control need to be fitted with a device to slow down the cage movement. Radial and Iris style cages are most common.