Reliable High Speed Film Sealing Slit Seal

Replace the Traditional Slit Seal Systems with High Quality Machine Direction Seals from D R Joseph, Inc.

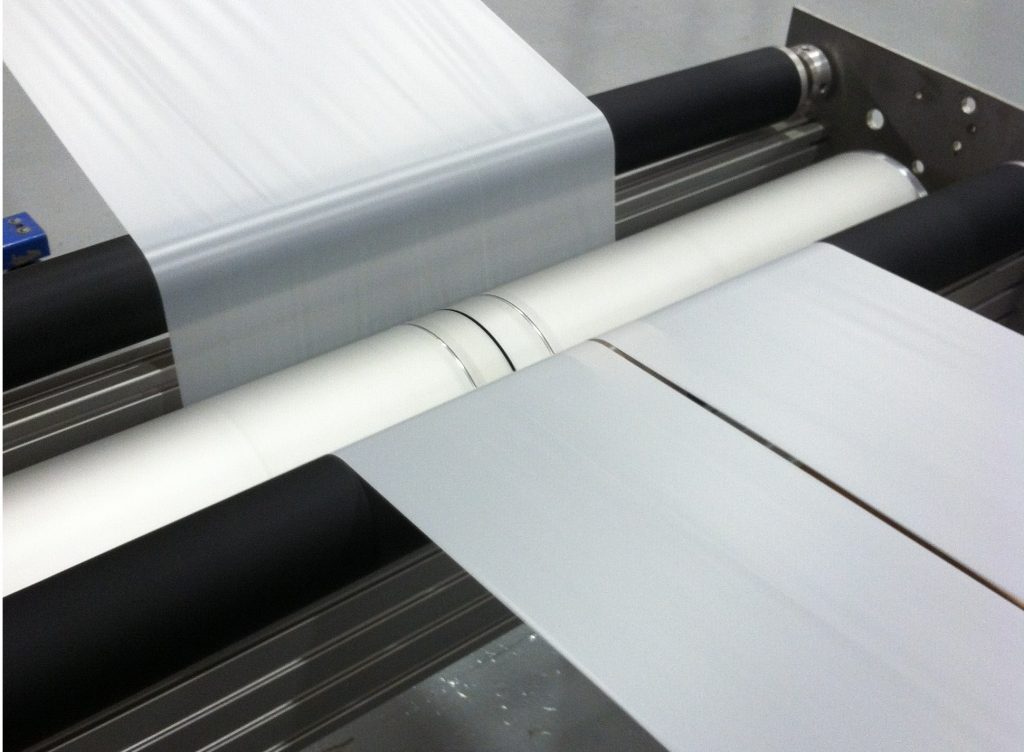

The high-speed Seal-Cut sealing system for plastic film offers an original, innovative solution that replaces traditional slit seal (hot knife) systems for machine direction sealing. The Seal-Cut is capable of producing high quality, sealed edges in a wide variety of film applications for better seal reliability and superior seal strength.

Versatility

The Seal-Cut is versatile. Not only thin gauges, but even heavy gauge jumbo or master rolls are easily converted into narrower tubes. Conversely slit seal systems cannot handle much more than 2 mil (50 um). Even multi-layer films can be sealed with the Seal-Cut. A machine like this saves production and equipment costs because you can run several webs of material from one larger line rather than needing several smaller lines to run the same number of webs.

Safe

The seal-cut uses a non-sharp sealing element and has no driven parts. The Seal-Cut operates below the ignition point of nearly all polymers, therefore eliminating the risk of fire should the line / web stop while the unit heat is ON… a common occurrence when using a traditional slit seal system.

Performance and Benefits of a Seal-Cut Slit Seal

- Capable of running faster speeds than a Slit-Seal System - up to 1,000 feet/min (305 mpm)

- Film Thickness up to 6 mil (152 microns) as compared with 2 mil (50um) for a slit seal

- For Layflat Widths from 24-136" (650 - 3450mm)

- Simple Design Concept

- Consistent and Reliable

- Convert Master Rolls into Several Smaller Sized Rolls

- Reduce Production & Equipment Costs

- Instant and Precise Temperature Control (+/- 1°C) Reaches setpoint in ~ 2 seconds

- Built in Spreader Rollers with hand wheel adjust for repeatable settings

- Easy to use 6” color HMI with Historical Temperature Trending for QC Checkpoint

Design Principle

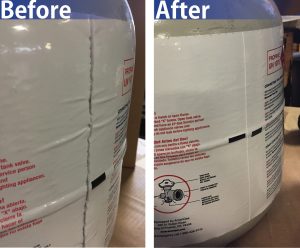

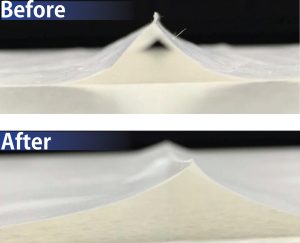

The Seal-Cut reverses the process commonly known as slit seal. Instead of slitting the material and then sealing it, the material is first preheated, then sealed and then the seal is split. This results in a clean seal, even on material up to 150 micron (6.0mil). For most materials, we use a significantly lower sealing temperature than the slit seal systems. For instance, a slit seal system has a sealing setpoint between 700 and 900°F (371 – 482°C). The Seal-Cut is set to less than half that temperature.

By sealing at a temperature near the melting point, seal crystallization is eliminated. A crystallized seal is brittle with inconsistent strength; which results in high roll return rates from your customers. Using the Seal Cut results in a high quality seal with excellent strength along the seal edge in both the transverse and machine directions.

Film Path Though the Unit

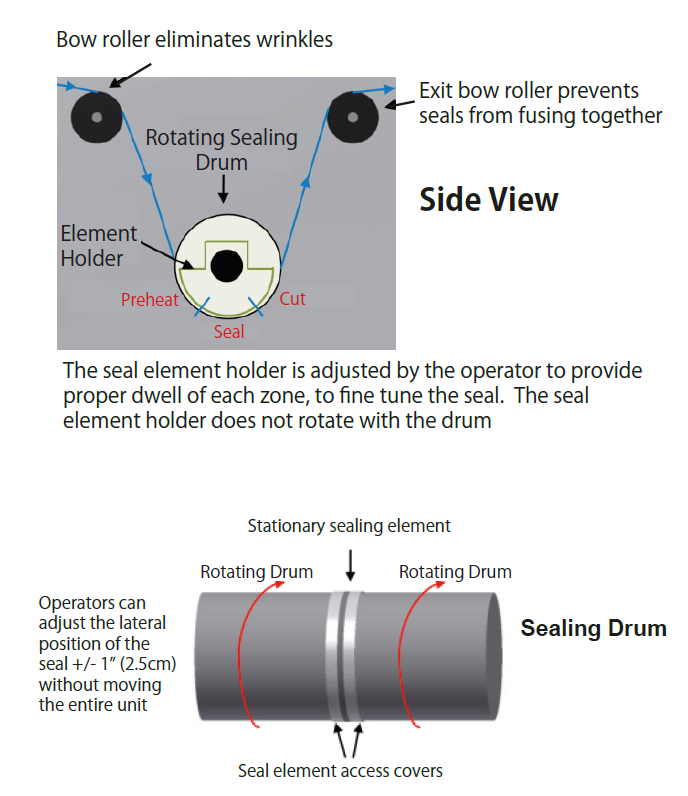

The diagram below shows how the web goes through the unit. The web passes under the sealing drum which contains the stationary seal element holder. The seal element itself has three separate zones: preheat, seal and cut. This three zone approach yields a sealing process that is more gradual and less of a shock to the material. You can even seal single sided metalized film, TPU, PA (Nylon) or biodegradeable film.

How to See Results With Your Film

If you are interested in seeing how the process will work for your material, we have a small lab to run trials with your actual material. Once you have the same roll, you can run it through your processes and make sure all stakeholders are happy with the results before you buy the machine.

Here are the specifications for the rolls we need: Please send two rolls of each material you want to trial. Maximum roll width is 19 inches. Core size is 3 inches. Maximum roll diameter is 12 inches. To setup a trial run, please call the office number listed on our Contact Us page.

We generally consume one roll to develop the process conditions and the second roll to run the samples which we send back to you. It is important that we also receive the following for each material to be tested: Typical line speed you want to run the material, and basic makeup of the material (% Low Density, % Linear Low, % Metallocene, % High Density).

We also can run a variety of lab tests on the seal (tensile, burst, etc.)

See a video of a Seal-Cut trial and tensile testing that we run here.

Sustainable Blown Film Investments Focus

Employing Machine Direction (MD) sealing in blown film extrusion allows producers to cut production costs and time in half by running a two‐up format.

A common investment in sustainable manufacturing is energy efficiency. The costs associated with powering extruders, die heaters, and winders (to name just a few) are high and production time is precious.

One possibility worth consideration is to run two‐up on your blown film line. You will find that beyond reducing the time and energy it takes to produce a given job, there are also other benefits such as improved film properties, thanks to a more advantageous blow‐up ratio.

In example, rather than dedicating two lines to producing a 20” layflat, running two‐up allows production to make a 40” layflat and then Seal‐Cut the tube into two smaller 20” tubes. Another way to put it: that same 20 hour long job will only take half the time on the same line, when employing MD sealing.

In terms of energy conservation, the savings calculation is simple: the Seal‐Cut is powered off of 10 amps at 110V, or 5 amps at 220V. Compare that to the energy requirements of a second blown film line, or double the run time of a single line to meet delivery requirements.

In terms of resource management, MD sealing expands the range of layflats that can be produced on a single line. For jobs that may require smaller layflats than a line is capable of producing while maintaining film properties, MD sealing puts smaller layflat within reach, reducing investments in additional resources.

The Seal‐Cut enables producers to provide a strong and reliable MD seal that customers can count on, while also meeting sustainability objectives.